|

Every year, crane accidents cause millions of dollars in damages in North America. Most of the time, corners may be inadvertently cut without crane owners and managers even knowing about it. With currently available technology, there is no reason to rely on safety training and operator awareness alone for the delicate operation of these highly productive but also highly sophisticated pieces of equipment. Prevention is as easy as having the proper education, experience as well as monitoring tools to ensure miscalculations and accidents don’t happen.

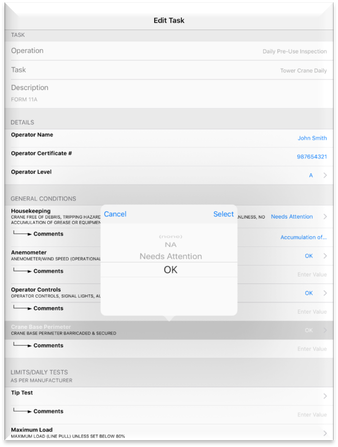

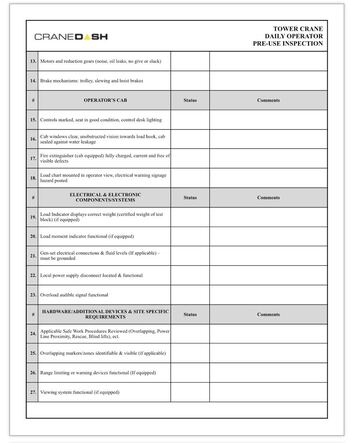

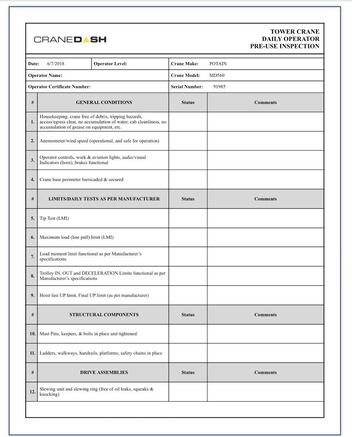

OptiCrane Inc. is at the forefront of this technology not only as a distributor of world-class viewing systems, crane safety products and anti-collision systems but is also a strong partner with Industry in the development and deployment of Management products to minimize documentation management hassles, ensure Preventive Maintenance is performed and overall crane management responsibilities from all parties involved are completed in a timely and effective manner. OptiCrane Inc. has developed an online application that allows all involved in the crane industry (from Regulators to crane owners, installers, maintenance personnel, operators and Supervisors) to ensure everyone’s responsibilities are met and foster an efficient and safe material lifting operation. So what is this Crane Management System? The latest addition to OptiCrane Inc.’s offering is the “CraneDash”. CraneDash is a leading edge fully portable on-line system that is specifically tailored to allow all contributors/users of Cranes to access and provide the required documentation as well as complete various forms to ensure all Regulatory and manufacturer requirements are met. |

COVID-19 Employee check testHere is a quick video of the CraneDash in action as an employee completes the COVID 19 health check.

|

|

CRANEDASH IS MEANT FOR CRANE OPERATORS, MANAGERS, OWNERS, RENTERS, SERVICE PERSONNEL, ENGINEERS, REGULATORS, ETC…

What are the benefits of adopting CraneDash?

Operators:

|

|

Managers:

|

Owners/Renters:

|

|

Service Personnel:

|

Engineers:

Access and check completion of assignment of responsibility report;

Regulators:

|

A proper safety program must also educate operators of Federal, State and Provincial Requirements regarding crane operation. It is crucial in making sure that all operators are aware of and abide by all the various health and safety codes, acts, and regulations legislated within their area of operation. Crane operators must also know how to properly maintain and inspect their cranes to meet applicable standards, and they must be properly educated on all the necessary pre-operational, operational, and post-operational requirements that must be followed as per Manufacturer’s specifications.

Supervisors must also be fully aware and be able to follow all safety rules and regulations and be able to monitor and evaluate each operator’s performance, taking appropriate action when an operator is not actively abiding by safe work-practices. They must have relevant knowledge, operator experience, instructional experience, excellent communication skills, and it is also highly recommended that they take an in-depth course in operator training before in order to become qualified.

A proper crane safety program is something that no company should compromise. The addition of “CraneDash” as the Management tool of your lifting units will undoubtedly allow everyone to efficiently and timely perform their duties to ensure the utmost due diligence and safety in the workplace.

Supervisors must also be fully aware and be able to follow all safety rules and regulations and be able to monitor and evaluate each operator’s performance, taking appropriate action when an operator is not actively abiding by safe work-practices. They must have relevant knowledge, operator experience, instructional experience, excellent communication skills, and it is also highly recommended that they take an in-depth course in operator training before in order to become qualified.

A proper crane safety program is something that no company should compromise. The addition of “CraneDash” as the Management tool of your lifting units will undoubtedly allow everyone to efficiently and timely perform their duties to ensure the utmost due diligence and safety in the workplace.